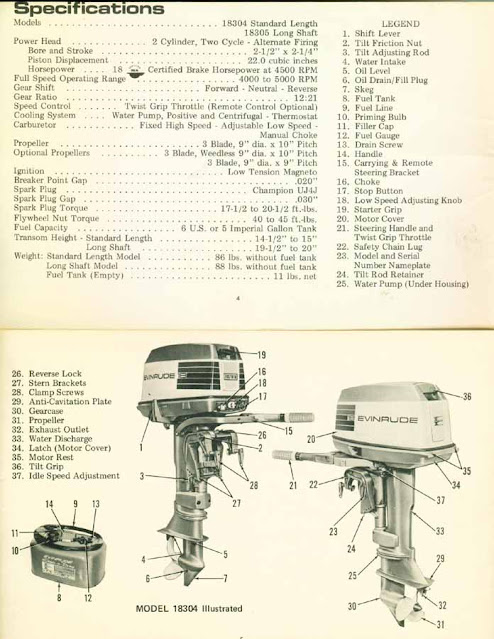

Picked up the first of many things to start off the "Mystnyx" Dianne's Rose project. I began a complete teardown on a 1963 FDL-17M which is an 18 HP Long-shaft Electric Start Johnson 2-cycle outboard. A relatively rare engine these days, but had a long and mighty run in the both the Johnson and Evinrude lineup, as OMC made Johnson and Evinrude 18's from 1957 until about 1973.

In that year, OMC changed the engine slightly, putting on bigger carburetor and began marketing it as a 25 HP. The old 18-20 hp Johnson/Evinrude motors were some of the best pound for pound motors ever made and very sought after these days. It was a good find for me at $200CDN, with a few things to be done, the motor was in a great condition overall.

Two-Stroke Versus Four-Stroke:

Most people shopping for a new motor assume that a 4 stroke is more powerful and, therefore, better. This isn’t necessarily the case. There are some advantages and disadvantages to each type of motor.In a two-stroke motor, the crankshaft will turn once for every cycle of the piston. This engine creates power once every two strokes of the piston, which means more bang, for a smaller sized displacement.

In a four-stroke engine the crankshaft makes two rotations for every one cycle of the piston. This means that power is created one time for every four strokes. This means the engine works less hard, on each power stroke, and is more quiet.

The two-stroke requires that oil be mixed with the gas which can be messy, and reduce fuel economy. Burnt oil out the exhaust can also smell. These engines don’t require you to add oil, are more fuel-efficient, and have greater durability. However most four-strokes require professional service maintenance, while the two-stroke is easily maintained and repaired by the average do-it-yourselfer.

|

| The OMC 18 H.P. outboard was made from 1957-1973 |

Making a simple outboard motor stand

- Coils - Ignition Coil and Lamination with Grommet OMC Part Number: 0584477 x 2

- Points & Condensers - Ignition Tune-Up Kit OMC Part Number: 0172523

- Spark plugs - Champion x 2

- Plug Wiring -7mm copper core spark plug wire with lacquer coated cloth braid over PVC insulation. 5ft Cloth Braided Spark Plug Wire Red W/ Black & yellow

- Fuel Filter & Gasket - Sierra International 18-2889-9 Marine Filter Bowl Gasket - Pack of 2, Fuel Filter, Small OMC Part 0308239

- Water Pump Impeller - Sierra International 18-3377 - Water Pump Kit 382468, Without Housing

- Rebuilt Carburetor - CARBURETOR SERVICE KIT OMC Part Number: 439071

- New Carb Float & Arm - Johnson/Evinrude/OMC New OEM CARBURETOR FLOAT & ARM 0396514, 396514

- Replaced/Upgraded Fuel Pump & Gaskets - Johnson/Evinrude/OMC New OEM FUEL PUMP & SCREW KIT 388685, Johnson/Evinrude/OMC New OEM GASKET 0303615, 30361

- Replaced all fuel lines

- Head gasket - Sierra International 18-2962 - Head Gasket OMC Part: 322332

- Exhaust gasket - EVINRUDE JOHNSON Exhaust GASKET 316162

- Replaced Thermostat and thermostat gaskets - Sierra International 18-0182-9 Thermostat Gasket - Pack of 2, Thermostat OMC Part 5005440, Thermostat Cover Gasket - OMC Part 0308328 - Thermostat Cover Gasket

No comments:

Post a Comment